The Cylinderblock

The Cylinderblock

A single piece presicion machined block made out of a high tensile, corrosion resistant, forged stainless steel. Built with front and upper caps giving easy access for inspection and maintenance. The standard design has spring loaded plunger packings with integrated water cooling. The design utilizes a minimum of parts and seals and is fully sanitary, suitable for C.I.P. plungers and plunger packings are available in different materials to meet the toughest demands. Besides the standard poppet and ball type pump valves, always with field replaceable Rexalloy®TM pump valve seats there are many options available to meet spesific product of requirements.

The Homogenising Valve

Available in a variety of design and materials, single or two-stage, with the standard flat valve and seat in Rexalloy®TM but also with a serrated surface (LW type) or knife edge for cell rupture applications. Each type specially designed to achieve the highest efficiency with the lowest energy consupption. The diffrent valves designs are available in the standard Rexalloy® material, Tungsten Carbide, Ceramic and for some applications with diamond coating. The homogenising pressures can be adjusted manually with a handwheel or through a hydraulic control which also allows a completely automatic pressure control.

The Drive End

The one piece high strength cast iron design with integrated gear reduction provides a quiet running machine with low eccentric shaft speeds. The drive has a dry sump with a seperate lubrication oil tank and does not require any cooling water. All bearings are pressure lubricated by an electric driven oil pump allowing capacity variation between 15-100% under full load. Both drive shaft and eccentric shaft have oversized roller bearings. The crossheads are designed with self adjustable, self aligning ball joint bearigs. This unique concept offers unbeatable reliability, requires a minimum of maintenance and down time.

Two Stage Homogenising Valve

Two Stage Homogenising Valve

A typical two stage homogenising valve assembly with a plug type valve in the first stage and a pilot type valve in the second stage. This assembly meets the highest demands for CIP cleaning, is easily accessible for maintenance and uses a minimum of parts.

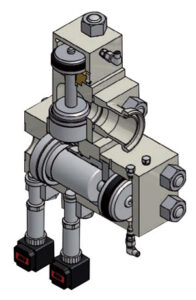

Cylinder Block

Cylinder Block

The pump block is a one piece precison machined block, made out of high strength corrosion resistant folged stainless steel. The one piece design utilizes a minimum of parts and seals, is fully sanitary and suitable for CIP.